Modular Mesh Generation

The CENTAUR Modular Mesh Tool offers the important capability to generate derivative meshes from an original mesh by re-meshing part of the geometry while leaving the rest of the mesh unchanged.

The advantages of the approach are minimization of the mesh changes and localization of the setup, yielding faster and more accurate re-designs.

Example: High-lift Wing

The type of elements on the flap surface is changed from prisms to hexahedra. The mesh changes locally only in the flap region:

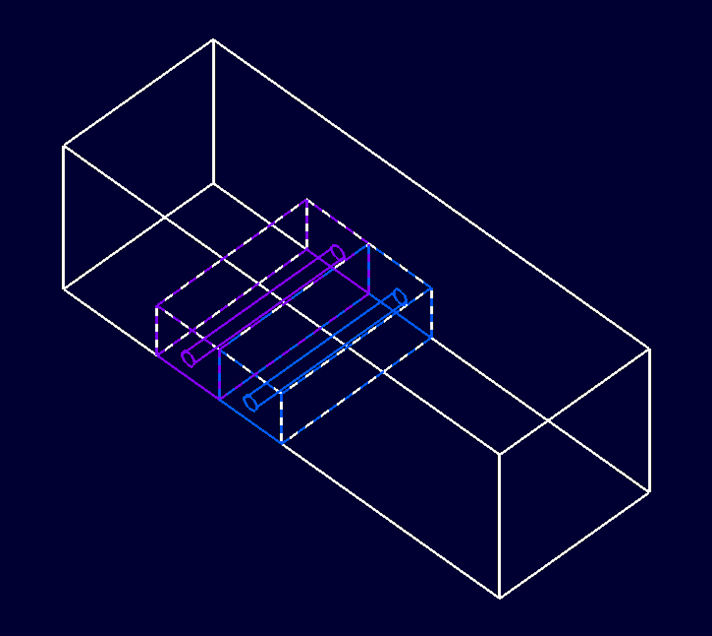

Example Channel

A local region/part of the geometry can be changed with only the corresponding local mesh being re-generated:

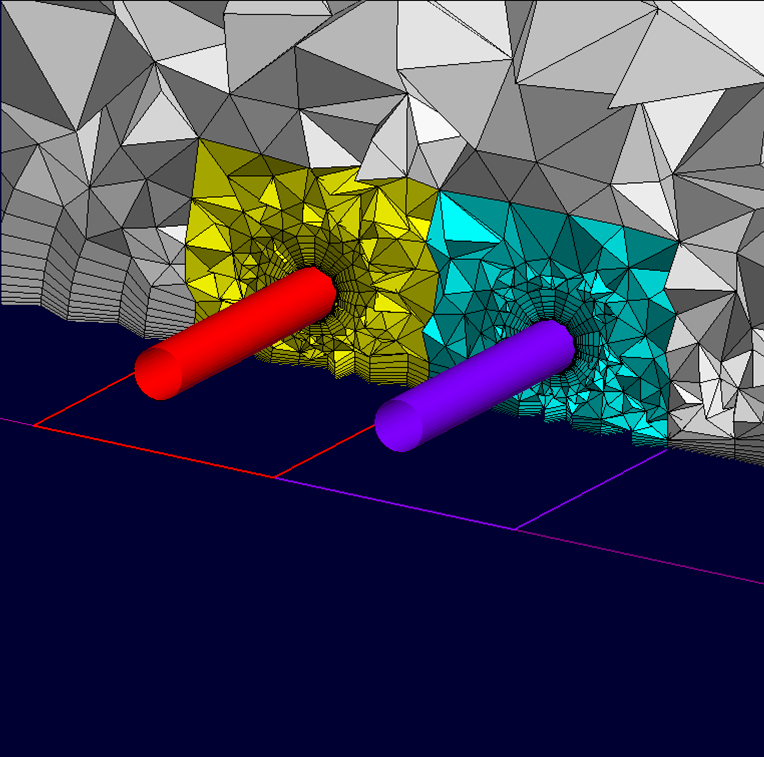

Example: Aircraft Engine Installation

The pylon connecting the aircraft engine to the wing is being re-designed. A box region is defined inside which the geometry and mesh changes will occur. The mesh over the rest of the aircraft domain remains the same thus reducing mesh variation which may skew the results.

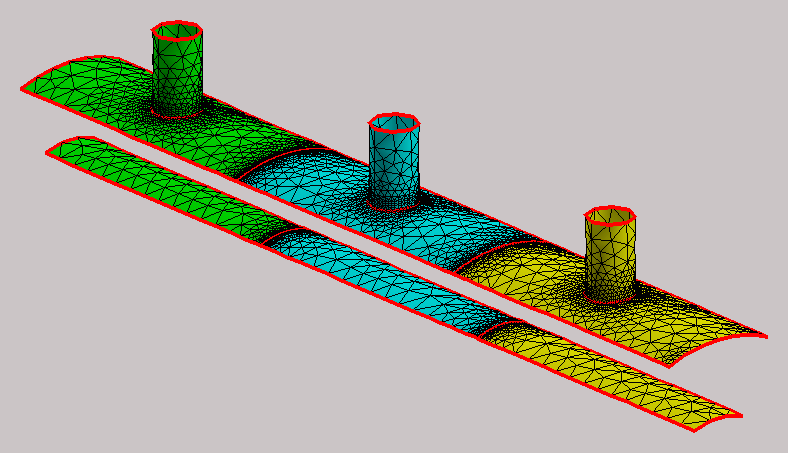

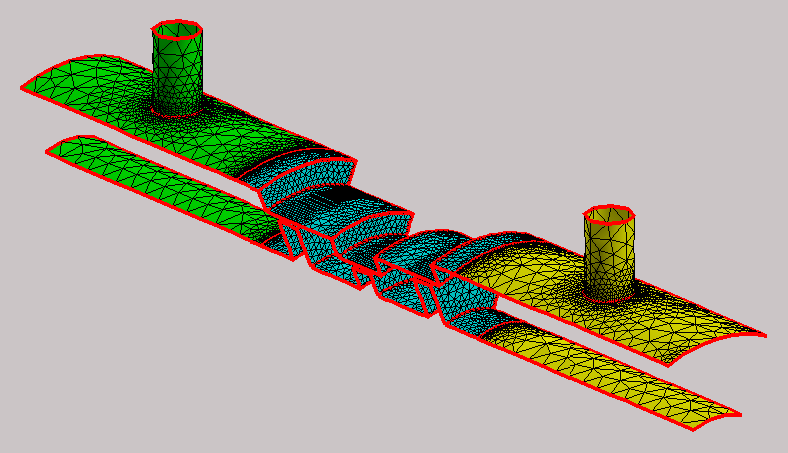

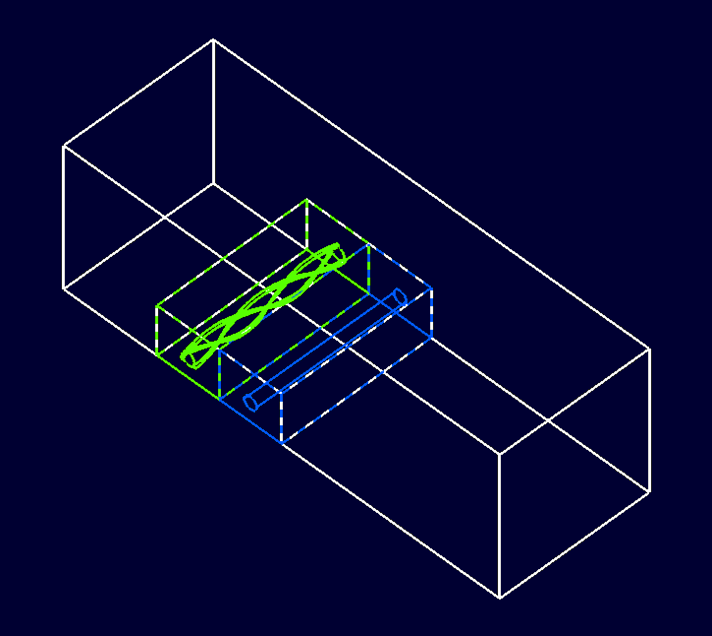

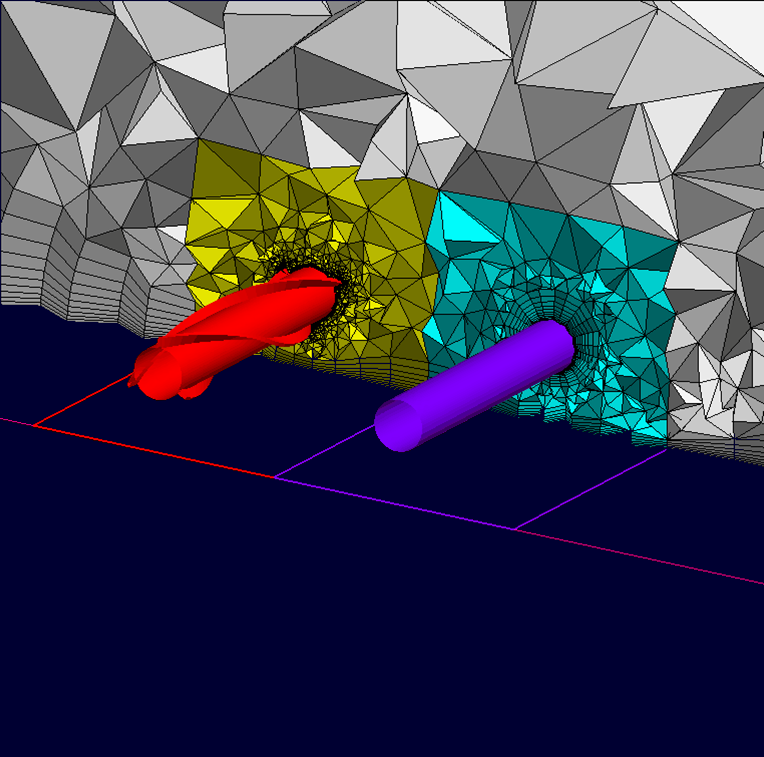

Example: Pipelines with and without helical strakes

This geometry regards the flow over two pipelines along the ocean floor. In order to prevent vortex induced vibrations, helical strakes are placed along the pipelines. Modular mesh generation can be used to replace the pipeline geometry with a straked one without regenerating the entire grid.