Four Cycle Internal Combustion Engine Analysis

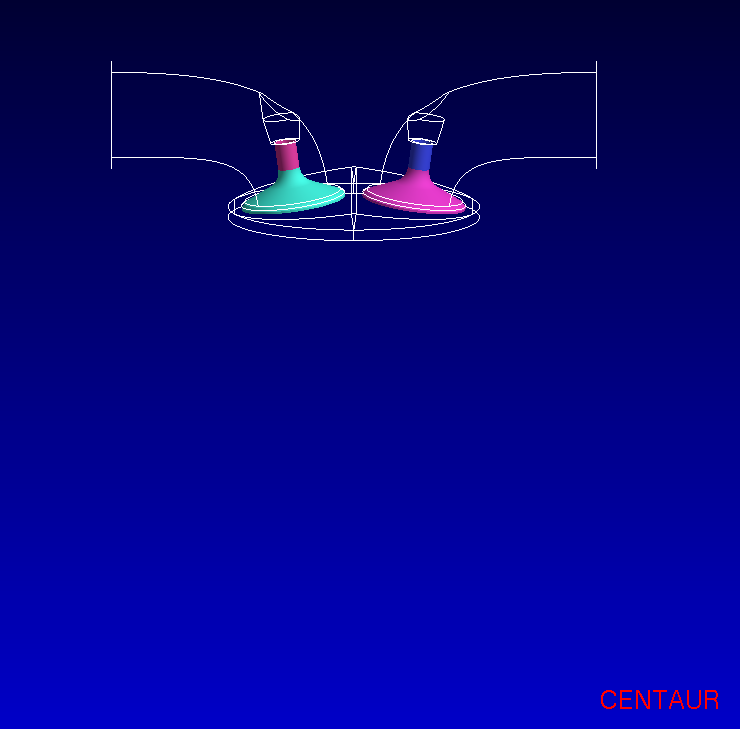

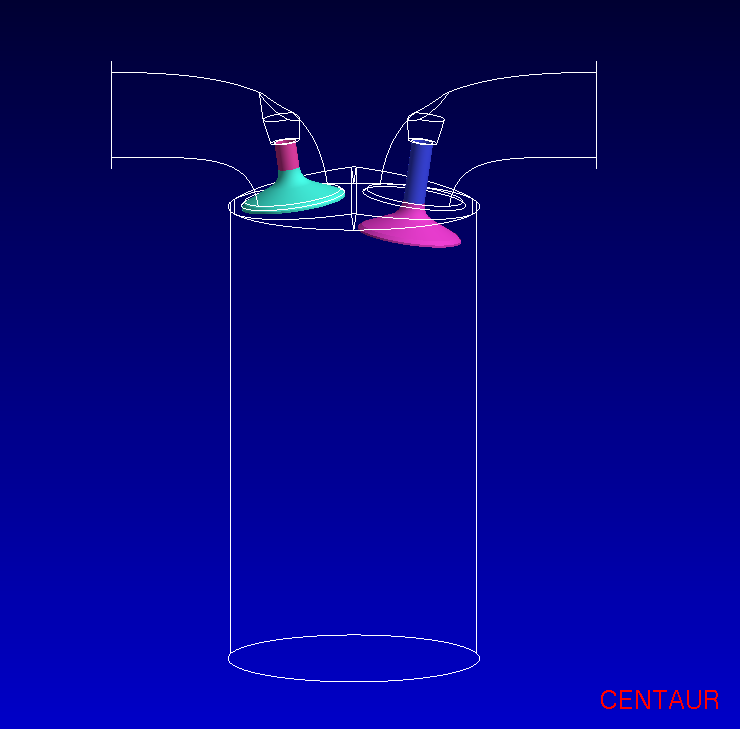

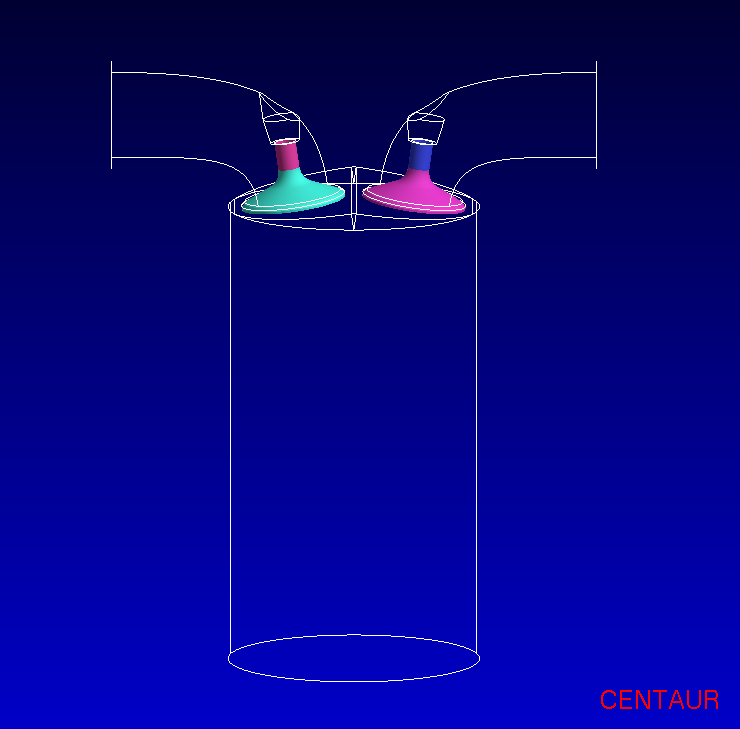

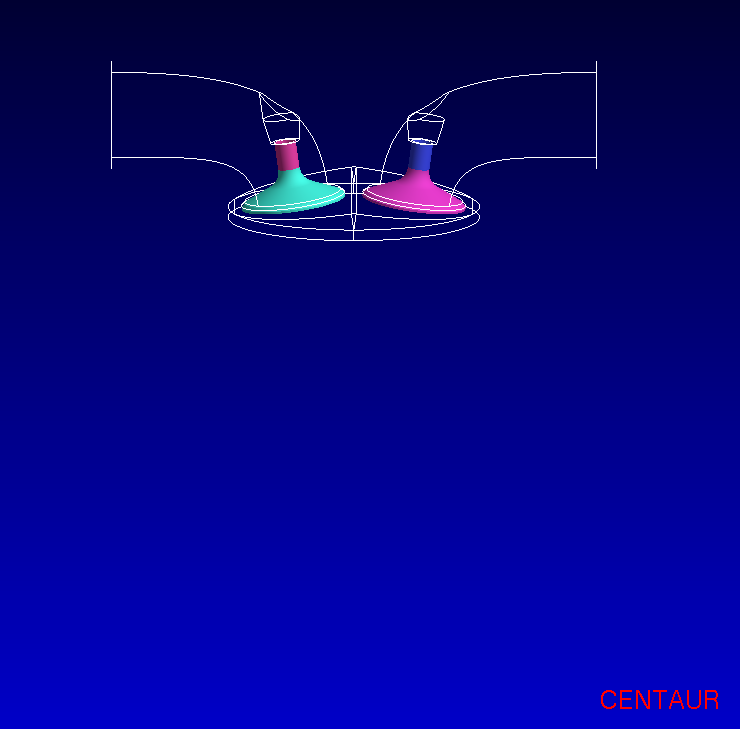

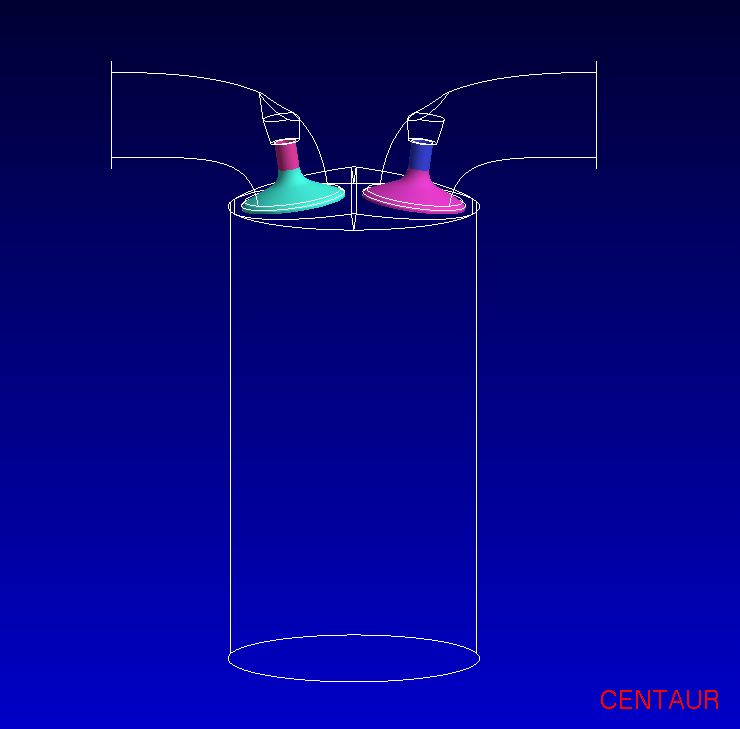

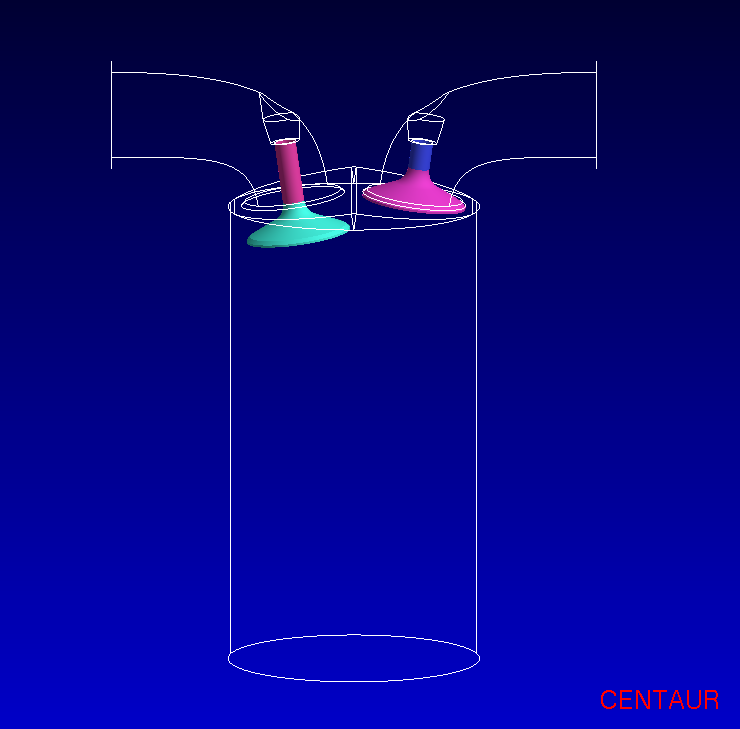

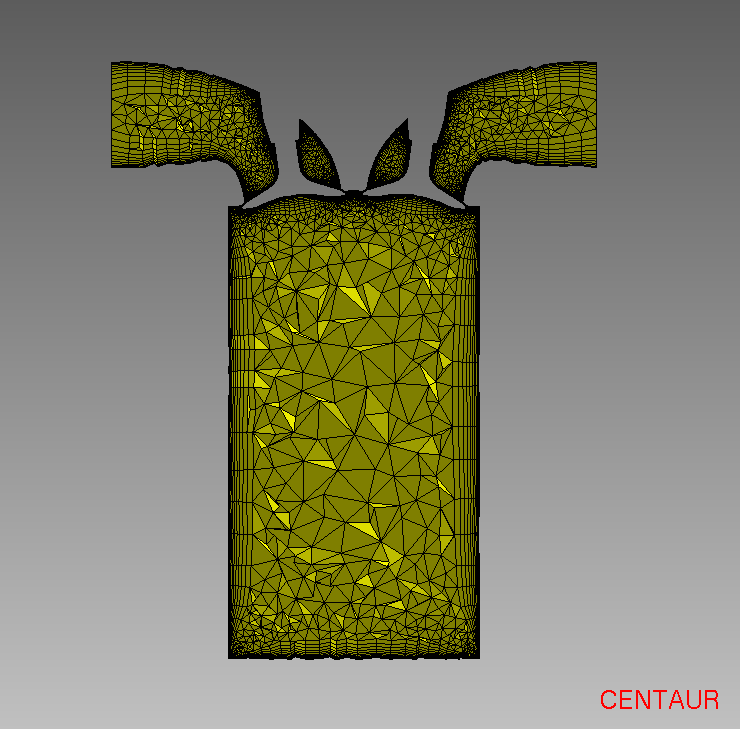

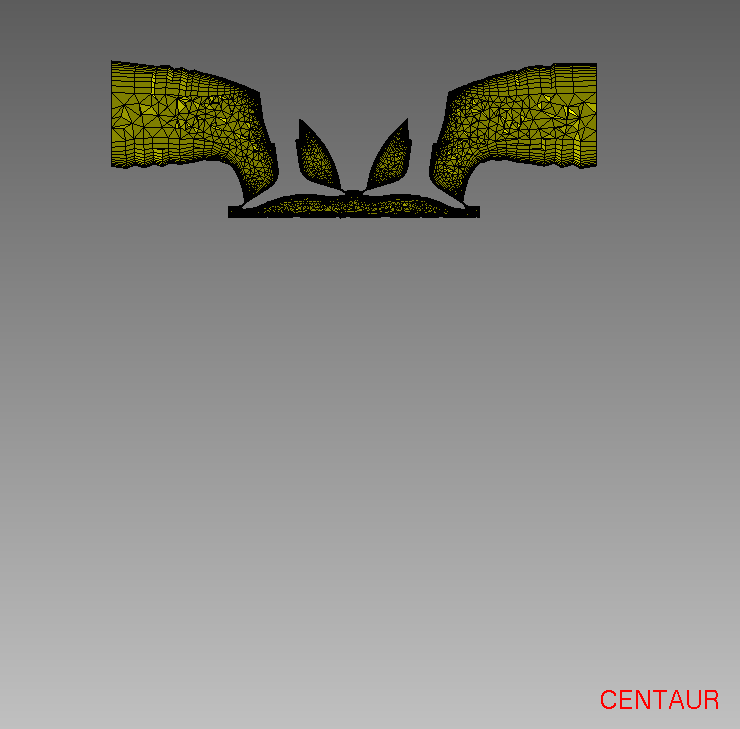

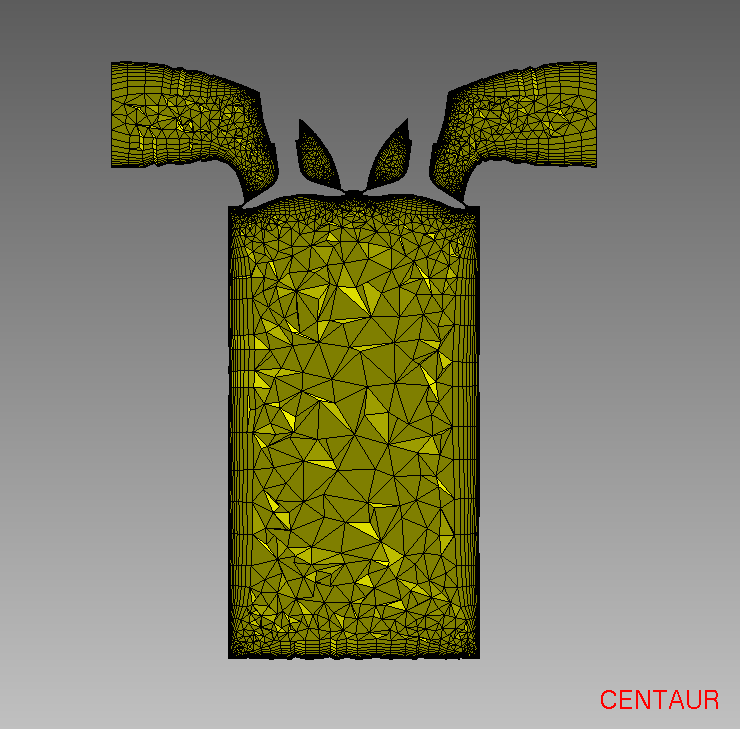

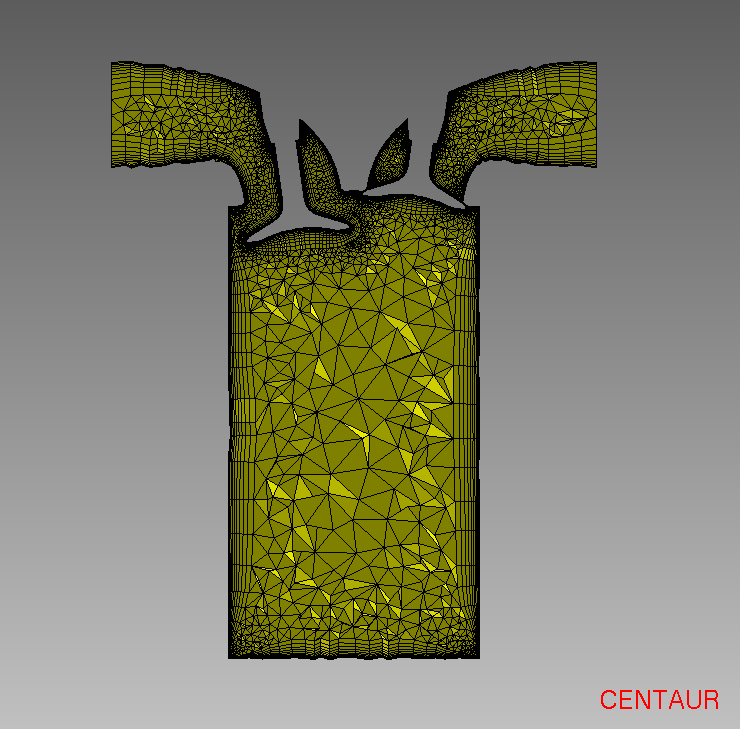

CENTAUR was used to create a hybrid mesh for one cylinder of a V8 engine. To simulate all phases of the motion involved in the entire 4 cycle process, multiple grids are created, and then mesh movement is used to create the intermediate grids needed for piston and valve motion.

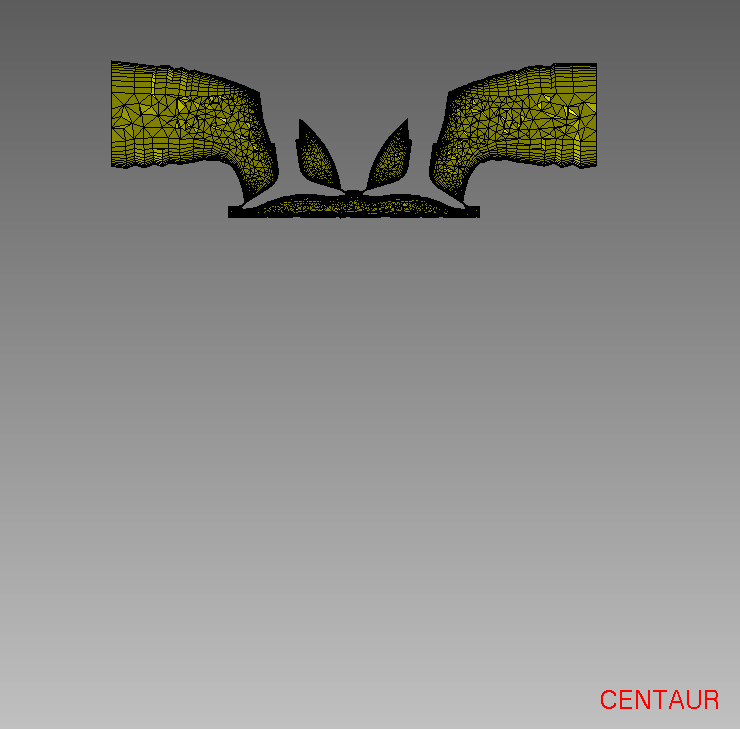

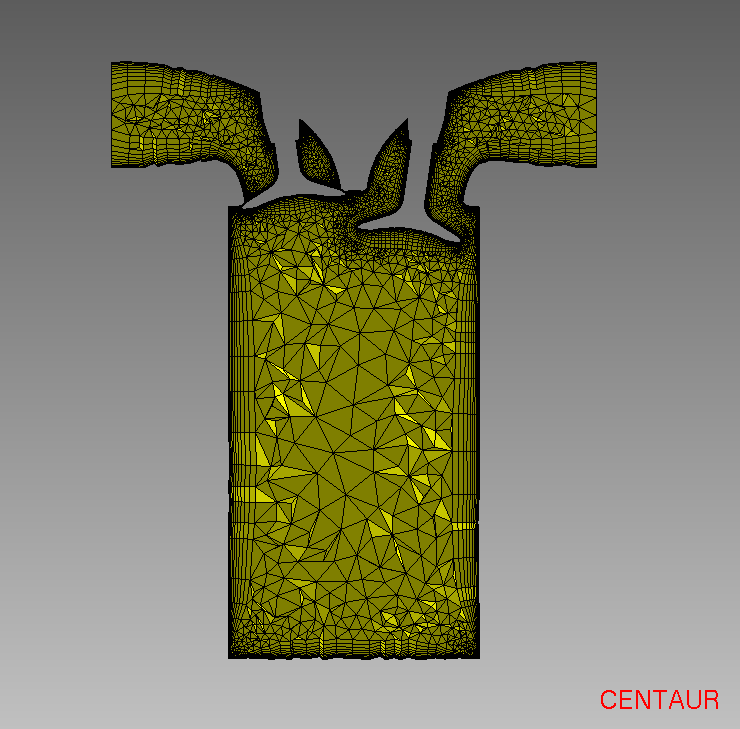

The pictures below show the cylinder geometry and the mesh for 6 phases of the combustion process.

The hybrid mesh contains both boundary layer elements as well as tetrahedra. All tetrahedral meshing can also be used. In addition, adaptive refinement can be used to dynamically adjust the mesh clustering based on the stage of the combustion process.